OUR SERVICES

CATALOGUE LINKS

- Metric Conversion Table

- Caps & Closures

- Adjustable Leveling Glides

- Hand Wheels & Control Knobs

- Banquet & Folding Tables

- Folding Table Legs And Flip Tables

- Table Bases

- Table Base Components

- Bar Gaming Stools

- Swivels, Rings & Weld Plates

- Office Chairs & Visitor Seating

- Office Chair Components

- Nylon Chair Bases

- Polished Aluminium Bases

- Twin Wheel Castors

- Lazy Susan Bearings

- Pallet Feet

- Saddles, Bushes & Washers

- Stool Steps

- T-nuts & Metal Tube Joiners

- Hand Grips

- Marine Canopy Fittings

Design

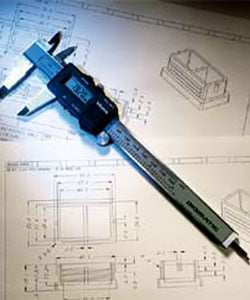

T&G Industries commitment is to focus on the services of assisting in design and development. Our experienced design team use the latest 3D CADKEY linked design system to create tooling to your specific requirements.

We offer a single site design, tooling and manufacturing environment.

WE USE LATEST DESIGN SYSTEM

We have been designing plastic products for years now, and we are committed to producing the finest designs using the highest quality materials. This ensures the very best results for our customers and helps to keep our reputation excellent within the industry. We pride ourselves on being able to meet and exceed our customers’ expectations, and we are always looking for ways to innovate and improve on our design process and on the results.

Our product designs are the results of decades of experience, and we work hard to ensure that they are cost effective for our clients. We can work with your budget and your project needs to give you doings that are right for you. Using techniques like mould-flow analysis, we can catch problems ahead of time and save you money. This can help us to make necessary changes before we ever get to the mould manufacture step, resulting in money and time saved for our clients.

You can contact us to find out if we are right for you and if our services can meet your needs. We will provide you with a free quote, and we can work with both large scale and small scale jobs, so we are the ones to call no matter what kind of design project you have in mind.

Feel free to talk to our design staff to get professional advice about your plastic product design. Our team can work with you to find out what your needs are, and they will follow up with you to set up a scoping meeting and to hammer out the various details of the project. Before we every start implementing a design, we make sure that our customers are on board 100% and that they know for sure what they are getting, how much it will cost and how it will meet their needs. We also give you estimates of how long the project will take

Scoping Process

One of our specialties is modifying and crafting plastic products that are used in mass production projects and for injection moulding. At that first scoping meeting, we will detail what our company is capable of providing for you and how we can work with your original design to improve the product or start from scratch to make something that caters specifically to your needs. We will work within the confines of your budget and timeframe and help you to get a plastic product that you can be happy with. At every step of the process, you are involved and informed, and this ensures that you are going to be satisfied with the result.

Designing through 3D Software

We at T&G Industries stay on the cutting edge of plastic design. We utilise 3D CAD software that helps us design in three dimensions and plan out a project in intricate detail before it is manufactured. This 3D model can be altered as needed to fit your specifications, and you can see how it might be implemented in your business. If you would like to know more about how we use 3D software and how it can benefit you, then please give us a call. We are more than happy to detail the way we use software.

For the most cost-effective plastics design in Australia, give us a call. We can handle all your design and injection moulding needs.