Food packaging has transformed since the start of the century. This has been partly because of the need for tamper proofing. It is also partly due to what appeals to the market. There is a new kind of labelling that answers both of those needs- injection moulding, which allows for labelling to be moulded onto the product seamlessly. It can be used in high volume production processes and takes the place of previous thermoforming technology.

How Scalability Becomes an Issue

Making containers with built-in labels was too expensive for smaller companies in the past. They had to use cheaper, lower quality labelling methods that would leave their products open to tampering. This is a particular problem for Australian manufacturers who are serving smaller scale populations than some of their global competitors. Many Australians are looking for artisanal products from companies that were actually running into issues with meeting the customer demand. In many cases, it was not possible to purchase packaging from an overseas supplier, particularly because of the issues with safety requirements and hygienic manufacturing. This meant that few to no local manufacturers were able to meet the needs of their clients in this area. As demand for high value low volume products was increasing, the market was facing a crisis.

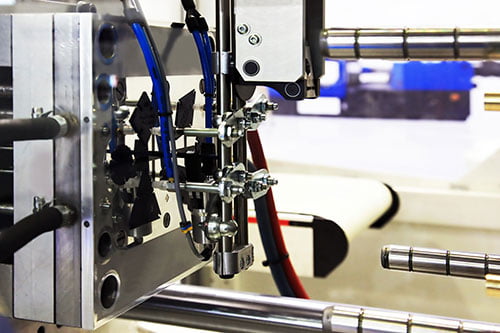

Injection moulding has recently been applied to the plastics industry in a breakthrough for this market. In-mould labelling was a step ahead of what other labelling techniques were offering. It could be performed in an affordable way on a large scale or a small scarlet, making it the perfect solution for companies with these kinds of requirements.

In-mould labelling has produced some impressive results. It can be used by artisan companies who need tamper-proof packaging and a sophisticated, bespoke look. They can now meet the needs of their clients and not have to charge them extra rates for the service. This method of labelling works equally well for common staples that are needed to be produced in mass quantities and niche items with a high value but with less demand for them.

These tamper-evident containers from T&G Industries is available in a wide range of sizes. It can be used to fulfil orders that require just a box of the product or an entire pallet. We are here for your needs, no matter how big or small they may be.